Shields surfaces from scratches, dust, and damage during storage or transit.

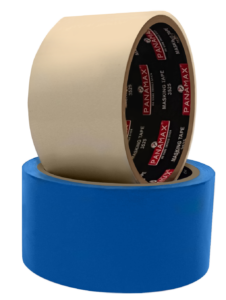

Surface protection film tape, also known as surface protection tape or temporary protective tape, is a specialized adhesive tape designed to protect surfaces from damage during handling, transportation, installation, or other processes. It is typically made from a thin, durable film material coated with a removable adhesive on one side.

The primary purpose of surface protection film tape is to provide a temporary barrier that safeguards surfaces against scratches, abrasions, dirt, moisture, and other potential sources of damage. It adheres securely to various surfaces, including metals, plastics, glass, painted surfaces, and more. The adhesive is formulated to bond firmly but can be easily removed without leaving residue or causing surface damage.

Request a customized quote

Contact us we will contact with you soon.

+91 9267989089

1800 999 2049

Panamax implements best practices to ensure top-notch quality, employing efficient processes, rigorous quality control, and industry-leading standards for superior service and customer satisfaction.

We ensure on-time delivery, providing reliable and punctual delivering services to meet customer deadlines and expectations.

With years of experience in the adhesive tape manufacturing industry, we bring extensive knowledge, expertise, and a proven track record of delivering high-quality products.

We hold a significant technical advantage in the tape industry, leveraging advanced technologies and innovative solutions for superior performance and reliability.

We prioritize transparency, fostering open communication and providing customers with clear and accurate information throughout their engagement.

We provides comprehensive end-to-end support, guiding and assisting customers at every stage of their tape-related needs for a seamless experience.

It is applied to protect surfaces such as floors, countertops, cabinets, and fixtures from scratches, stains, and spills.

It can be used for various creative projects like scrapbooking, card making, and stencil designs.

It can be applied to protect car exteriors, headlights, bumpers, and other vulnerable parts from scratches, chemicals, and UV damage.

It is commonly used to protect screens and surfaces of electronic devices, such as smartphones, tablets, laptops, and gaming consoles.

It is applied to furniture and appliances during storage, transportation, or assembly to prevent surface damage, scuffs, and scratches.

It is used in painting and decorating applications to create clean paint lines and prevent paint bleed on surfaces such as walls, trim, windows, and furniture.

It is used in exhibition and trade show displays to protect graphics, signage, and booth surfaces from damage caused by handling, transportation, or foot traffic.

It is applied to glass surfaces, windows, and mirrors to protect them from scratches, chips, and shattering during handling, transportation, or installation.

Shields surfaces from scratches, dust, and damage during storage or transit.

It is designed for easy application, allowing for quick and efficient coverage of surfaces.

It is highly resistant to tearing, puncturing, and impact, providing reliable protection for surfaces during transportation, storage, or construction activities.

It is compatible with a wide range of surfaces, making it versatile for use in various industries and applications.

The adhesive used in surface protection tape allows for easy and clean removal without leaving sticky residue or damaging the underlying surface.

| It can be customized to meet specific requirements, such as color-coding for identification or printing with company logos, handling instructions, or other information. |